Transformer Conditioning System: TRANSCOND

Transformer conditioning systems are needed to keep the actual substantial condition of a transformer in order to extent the life time and/or improve reliability and security of the service. The system removes the feared ageing accelerators water, oxygen and particles due to the integrated high grade filtering.

The necessary data of secure service, especially the Break Down Voltage (BDV) will be restored within a short time. The long term reliability and electric strength will be restored or maintained because of the improved homogeneity in the insulation system and the low oxygen content, the latter measure stops nearly the ageing deterioration.

It is possible to keep even transformers with a remaining life time strength below 50%, which have normally a very limited utile life under 5 years, for 5-15 years longer in service, without jeopardizing the reliability of service and energy supply to the customer.

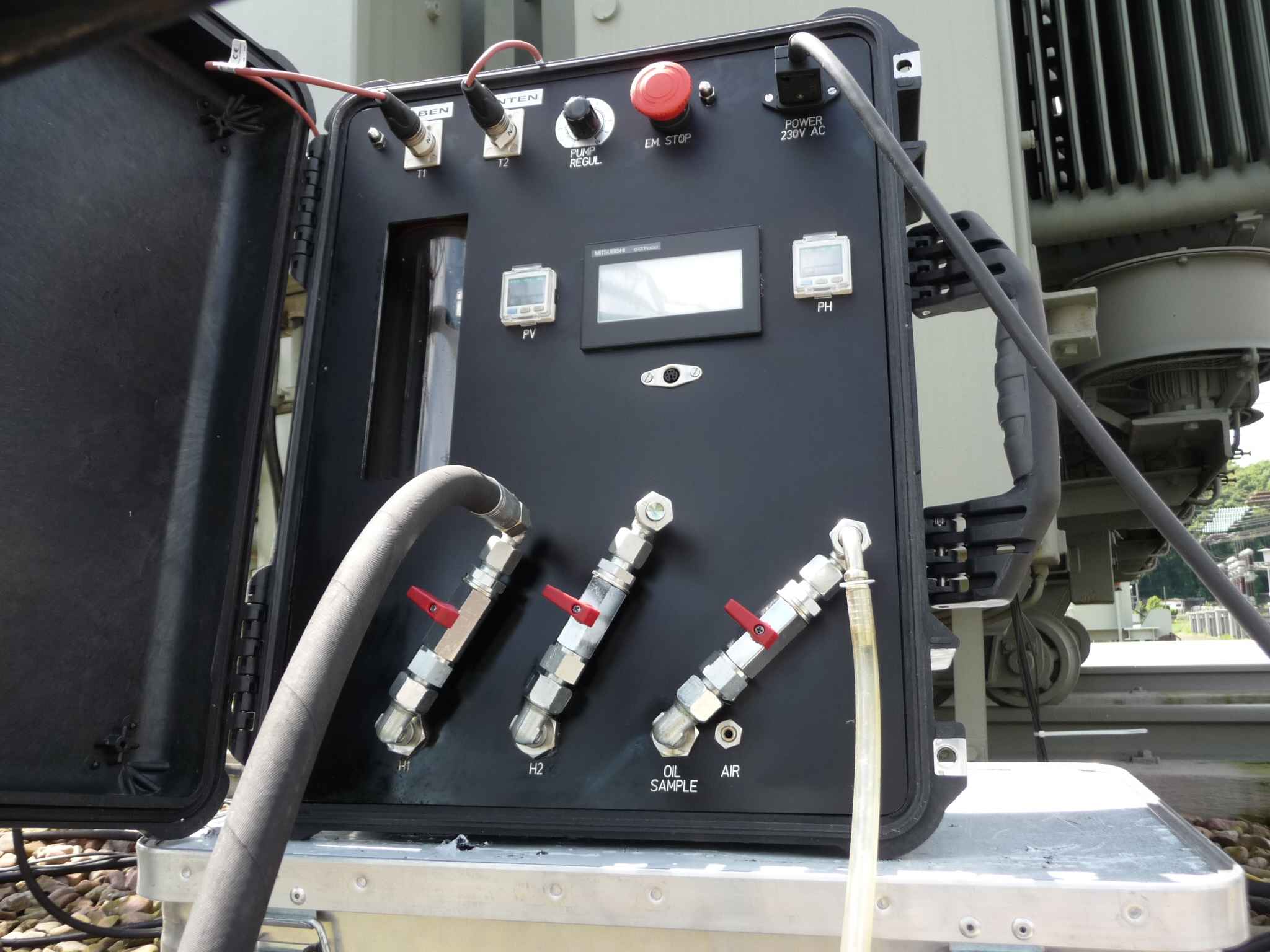

Online Water Content Measurement of Transformer oil: TRANSDIAG

The most reliable way to determine the water content in transformers is by determining the relative moisture. In that case both media have the same water content. The known characteristic conversion curves are used to determine the water content of the cellulose in vol. %. To that end the device is attached either to the “top” and “bottom” oil probes or to the “top” or “bottom” probe.

The most reliable way to determine the water content in transformers is by determining the relative moisture. In that case both media have the same water content. The known characteristic conversion curves are used to determine the water content of the cellulose in vol. %. To that end the device is attached either to the “top” and “bottom” oil probes or to the “top” or “bottom” probe.

The “top” and “bottom” temperatures are then measured via the sensors. This measuring process must be continued for an adequate length of time (i.e. at least 30 min) to ensure that the transformer is not in a dynamic condition of change.. The rugged mechanic system allows also long term measurements. Other measurement systems can be integrated in order to have a temporary monitoring device.